Rubber 3D Printing Services:

3D Printed Rubber Applications:

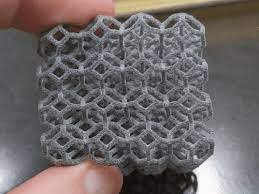

The versatility of 3D printed rubber parts extends their usability across a wide range of applications. Serving as a viable alternative to molded rubber. Similar to other 3D printing methods, rubber printing offers precise replication of intricate internal geometries. Such as lattices and tubes, without incurring additional costs. This capability enables the realization of designs that would be impractical with alternative manufacturing processes.

Unlike traditional methods like injection molding that involve expensive molds and tooling. 3D printing eliminates the need for such costly infrastructure. As a result, 3D printed rubber parts can be produced within a few days. Contrasting with the multiple weeks of lead time required for injection molding. This unique combination of rapid production and minimal start-up costs positions rubber 3D printing. As an excellent choice for both prototyping and small- to medium-sized production runs.

Advantages of 3D Printed Rubber vs. Injection Molding:

Historically, rubber manufacturing relied on processes such as injection molding, casting, or sheet lamination. As rubber-like materials were too soft for conventional machining. Additionally, early in the evolution of 3D printing, the technology was primarily limited to harder plastics. However, recent advancements in 3D printers and materials have ushered in a transformative era, expanding the potential for creating a variety of 3D printed rubber products. How does the process of 3D printing rubber compare to traditional methods like casting or injection molding in terms of manufacturing efficiency and outcomes?

3D Printed Rubber Materials and Technologies:

Whether 3D printed rubber qualifies as true rubber depends on individual perspectives. The term “rubber” encompasses a range of materials, including thermoplastic polyurethane, thermoplastic elastomer, silicone, and, notably, natural rubber.

Natural rubber, also referred to as latex, lacks the capability to undergo the liquefaction and re-solidification process required by 3D printers. In contrast, thermoplastic elastomers can emulate the flexibility and softness of rubber while possessing the necessary thermal properties for 3D printing.

Among the most effective rubber-like materials for 3D printing are semi-rigid thermoplastic polyurethane (TPU) and soft shore photopolymers, exemplified by our High Rebound Elastomer. TPU undergoes heat fusion through a thermoplastic powder bed process known as Multi Jet Fusion (MJF), while photopolymers, as suggested by the name, are cured by light through stereolithography (SLA).

Rubber 3D Printing Services:

Rubber and rubber-like materials play a ubiquitous role in contemporary industry. Flexible and durable soft materials such as latex, silicone, and thermoplastic elastomers find applications in both industrial components and consumer goods. Traditionally, rubber manufacturing has been dominated by casting and injection molding processes. However, recent advancements in 3D printing technology and materials have positioned additive manufacturing as the preferred method for producing small to medium quantities of rubber-like parts. Our 3D printed rubber services offer the capability to produce high-quality rubber-like components in as little as two days, requiring only a 3D model to begin the process. Whether for industrial or consumer use, our quoting tools allow you to obtain a project estimate promptly. Our team of engineers will review your project and provide a response within 24 hours.