Know About Composite Panel Board?

The term “composite” refers to the combining of two or more parts to create composites with unique characteristics and traits from their original raw ingredients. Composite panel boards are made of sheets that link together so that two covering layers cover a core layer. Depending on the application, the polyethylene rubber core layer’s thickness ranges from around 3 to 20 mm.

These wall panel boards have been manufactured since the late 1960s. Since then, the use of these wall panel boards has altered the urban and industrial environment in many locations since composite wall panel boards provide designers and builders an almost limitless range of options due to their distinct qualities.

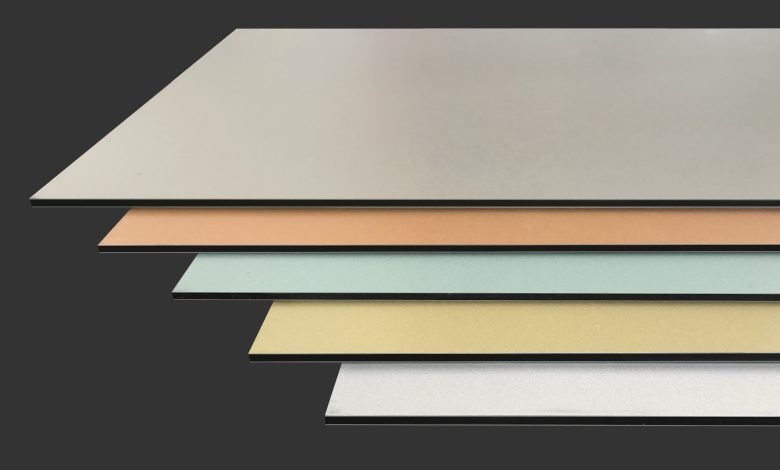

Composite panel board types according to the outer layer

The thickness of the center plate affects the types of panel boards. For instance, there are divisions based on coatings for wood paneling, nano-panels, antimicrobial panels, stone-laying panels, fire-resistant composite panelskiva, and more.

Different types of aluminum composite panels are created by using various paint and shielding layers. To increase the effectiveness of insulation, some materials could, for instance, be coated twice or with a polyester coating.

The use of composite wall panel boards

By itself, polyethylene rubber is used extensively in industries like building, installations, insulation, flooring, and so on. The panel boards depend on the usage. Either they are installed on the roof or in other areas.

Strengths and advantages of composite wall panel boards

- These panel boards can be recycled and utilized again in the same sector of the economy.

- Because they will be cut in predetermined sizes to bend or install more easily, the workflow and installation of these sheets are rapid and much easier than with other materials.

- Rubber made of polyethylene is a petroleum product. This rubber acts as an insulator for energy and moisture because of the tissue’s porosity, which ties up air molecules.

- In spite of the fact that the kind and color of these plates may cause varying amounts and types of dirt and dust to accumulate on them over time, cleaning these panels doesn’t call for any specialized equipment or laborious effort, and they are really very simple to perform. Another variety of composite panels is one that resists contamination and is anti-bacterial.

- One of the most well-liked components of these panels is their lightweight and great strength, which broaden the variety of possible applications.

- The installation process for these panels is quick if you have access to knowledgeable personnel and specialized tools.

These pages are distinct from one another and when combined would make a set. The destruction of a portion of the collection does not always indicate that the entire collection is in danger. It is possible to independently fix or replace parts. Only by eliminating the damaged pages can the issue be fixed without harming the entire collection or necessitating removal and reinstallation.

Variations in the panel’s appearance and in the work produced

These wall panel boards are made in a variety of hues, textures, and designs. Access to all that would be anticipated of these sheets is supplied already. The facade of the building may alter depending on the laminate or matte finish’s color and composition. In comparison to employing organic and natural materials, they also offer a benefit. For instance, composite sheets with a wood design are less expensive than actual wood, and unlike wood, do not rot or decay, have no effect from the sun on their color, and are insect-resistant.

Since these väggpanel skivor have been regularly used, the limitations on the use of façade designs and decorations have vanished, and there has somehow been a revolution in both external and interior design. A succession of these plates might be used to form a homogenous, three-dimensional volume on the building’s exterior, or wall panel boards of various sizes and angles could be used to construct various 3D geometric volumes. Additionally, it is possible to create any type of mosaic or another pattern on any surface by cutting the plates into regular shapes and sizes.

These plates finally become flexible enough to bend and curl on the arching form of the structure. These curves’ flexibility, in contrast to earlier rigid and static structures, removed all limitations on design and implementation.

Read more: What Can I Put on My Composite Decking?